Sustainable Innovation

In response to global climate change and the goal of achieving net-zero carbon emissions by 2050, in 2022, Rexon began to establish its presence in outdoor vehicle motors. In addition to presenting innovative product concepts and proposals to customers for evaluation and adjusting their product lines accordingly, Rexon also focuses on enhancing the added value of its products through discussions on product features and specifications, pricing, market channels and promotion, profitability, and other aspects. This aims to assist customers in improving their competitiveness.

Product and Technological Innovation _

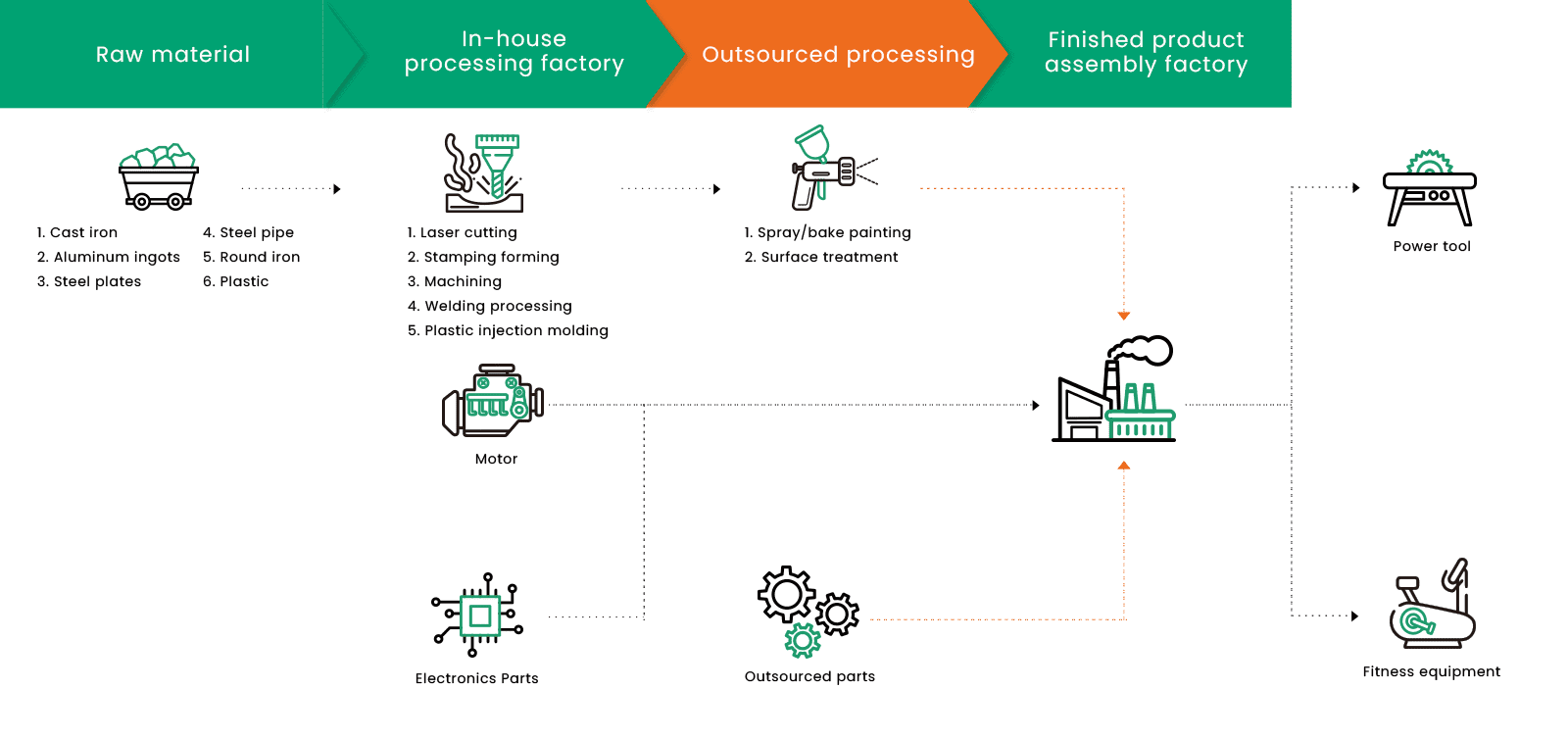

Rexon primarily focuses on the production of power tools and fitness equipment. Unlike many domestic and international competitors in the power tools and fitness equipment manufacturing industry that diversify their brands and distribution channels, leading to competition between retail and brand customers, Rexon faces significant pressure of potential losses due to systematic risks in the market environment. Therefore, Rexon is committed to enhancing its manufacturing capabilities and product quality. Vertical integration in the upstream and downstream processes as well as in-house production of critical raw materials are strengths of Rexon. The production process includes casting, stamping, tube bending, CNC machining, plastic injection molding, welding, motor production, control panel production, and product assembly. From raw material processing to final product shipment, Rexon has the crucial ability to integrate the entire system.

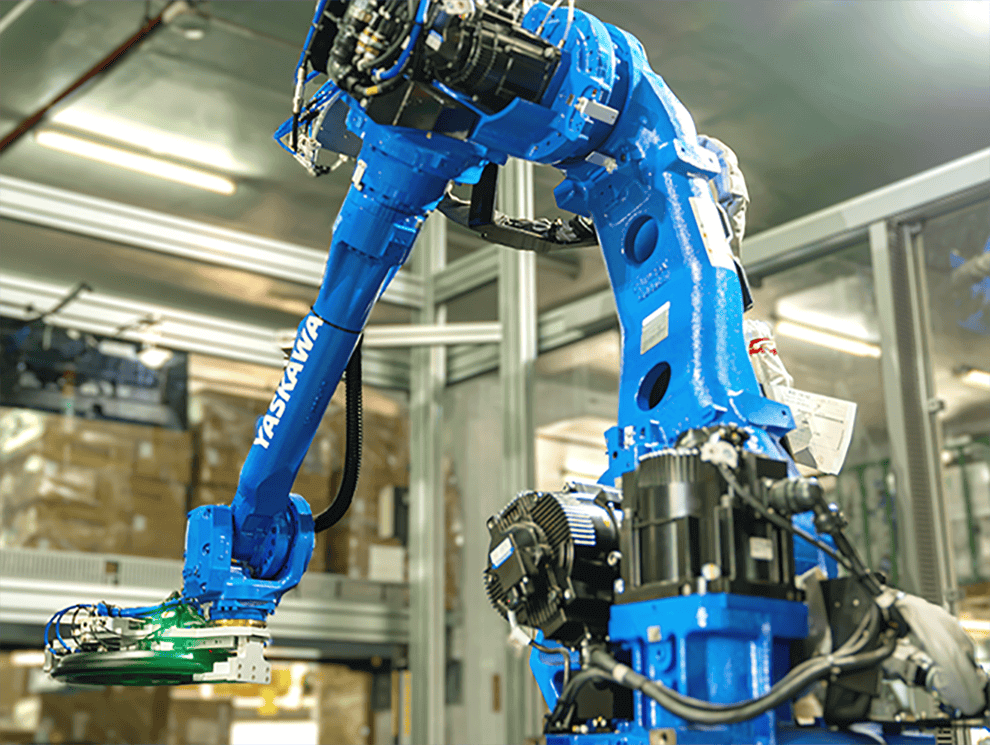

Automated production line for flywheels

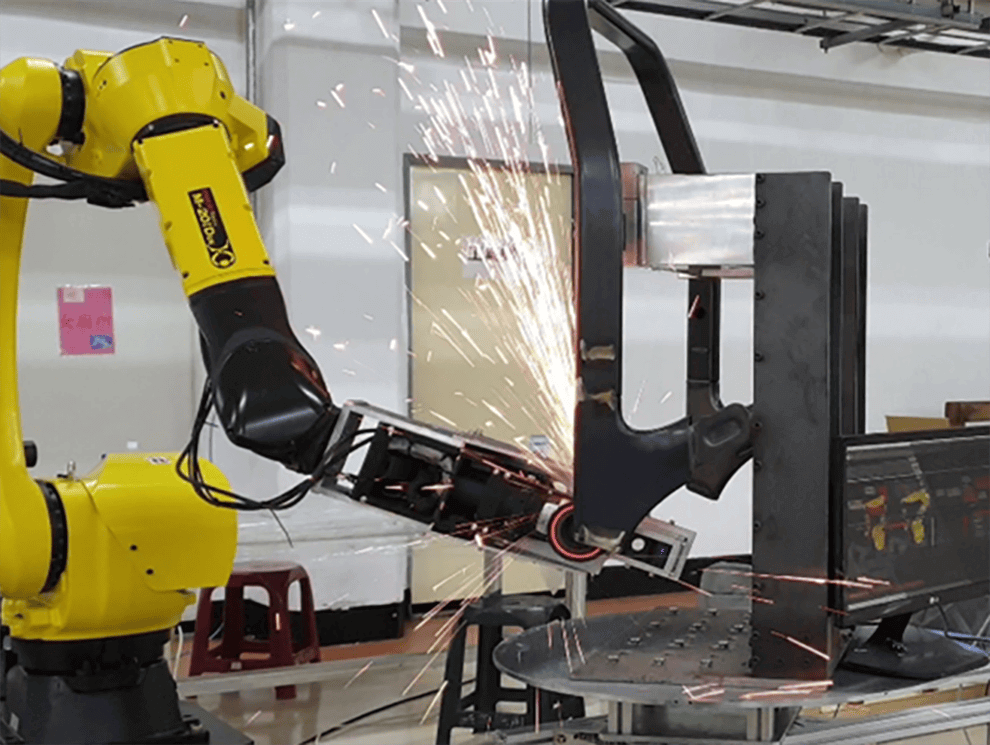

AOI Technology - Unmanned Grinding Equipmen

Automation in manufacturing processes

Vertical Integration Capability

In-house manufacturing by Rexon

Outsourced procurement by Rexon

R & D Investment _

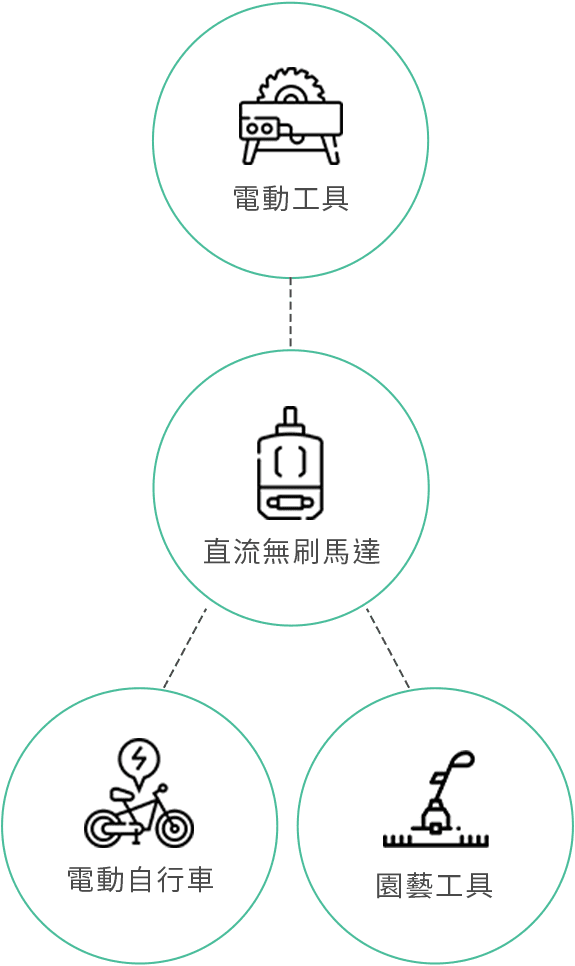

Rexon continuously innovates its power tool products, providing products that surpass customer demands. Through brand and retail store strategic alliances and the utilization of production sites, Rexon achieves product diversification. Since 1986, Rexon has been dedicated to developing high-performance motor and driver applications, investing in assembly production lines and automated winding equipment. In recent years, Rexon has gradually introduced BLDC (Brushless DC Motor) motors into newly developed product categories such as power tools, e-bikes, lawn and garden tools, and more (as shown in the diagram). By utilizing the high efficiency of BLDC motors, products can make more effective use of energy, resulting in savings and reducing unnecessary energy waste.

Green Products

In recent years, Rexon has been actively developing BLDC motor drivers, providing products with excellent efficiency and reliable quality to help customers stand out in the market competition. Currently, Rexon has developed three models of BLDC motors and drivers as shown in the diagram, which are applied in the MITER SAW, TABLE SAW, and drilling machine respectively. These BLDC motor drivers contribute to the green product initiative by improving energy efficiency and reducing environmental impact.

Green Components

In 2022, Rexon began expanding its portfolio of outdoor-use motors in response to the environmental demands of achieving net-zero carbon emissions. Apart from continuously proposing innovative product concepts and suggestions for customers to evaluate and adjust their product lines, Rexon also focuses on enhancing the added value of its products through aspects such as functionality, specifications, pricing, market channels, promotion, and profitability. This approach helps customers enhance their competitiveness. Starting in 2023, Rexon will commence mass production of the MR22RX center-position motor and the MR2201US walking motor.

FEATURES

- Three-phase output

- Adjustable speed

- Current limiting and circuit breaker protection

- Open/closed loop mode

- Configurable indicator output

- High efficiency

- Low electromagnetic interference

- Modular installation capability

Customizable motor casing and mechanism

Patent Fields and Distribution _

Rexon Industrial recognizes that innovation is the driving force behind business growth, and patents are crucial to its research and development endeavors. The company firmly believes that the fruits of collaborative efforts between internal employees and customers should be protected by intellectual property rights. These patents safeguard the valuable innovations created through joint development.

USA

USA /

Taiwan

Taiwan /

China

China /

Scroll

86

Number of Patents in Taiwan

49

Number of Patents in China

51

Number of Patents in the United States

3

Number of Patents in other countries

(Thailand: 1, Mexico:1,South Korea:1)

Number of Patents

We have accumulated 650 patents, out of which 191 are currently active and applicable to our products. We continue to increase the number of active patents each year. Additionally, we have implemented the EPS patent management system to protect and develop our intellectual property rights, enabling us to provide unique products and services to our customers.

Patent Count Statistics – Patent Classification

| Type | Number |

|---|---|

| Fitness Equipment | 49 |

| Power Tools | 122 |

| Outdoor Power Equipment | 9 |

| E-mobility | 7 |

| Powertrain | 2 |

| Total | 189 |

Taiwan

46%

China

26%

The United States

27%

Other countries

1%

Percentage of National Patent Counts

Electric Tools

65%

Fitness Equipment

26%

Outdoor Power Equipment 5%

E-mobility 4%

Powertrain 1%

Percentage of Patent Classifications

Sustainable Supply Chain

In line with Rexon's "co-prosperity” philosophy, the company incorporates ESG practices into its collaboration with suppliers, aiming to reduce the negative impact of business activities on the environment and society.

MANAGEMENT

Sustainable Supplier Management _

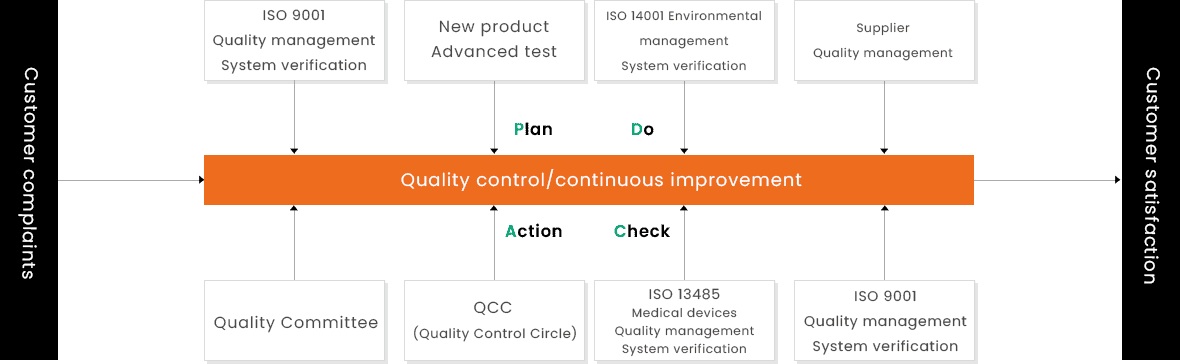

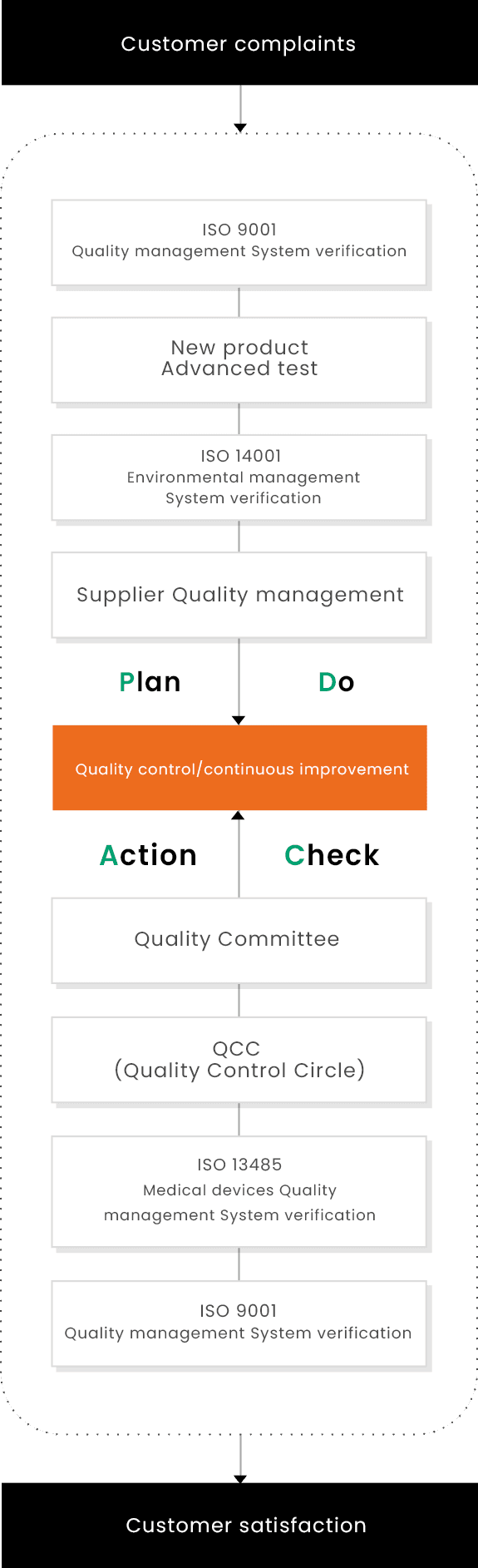

Rexon has rigorous mechanism and implementation guidelines for materials, components, and new supplier introduction in its supply chain. From new product planning to mass production, there are phased objectives and management/implementation regulations. While meeting customer demands, purchasing risk management is also considered, and a comprehensive supplier management system is established based on the PDCA management cycle. The operational approach includes supplier "development"→"certification"→"procurement"→"management evaluation"→"continuous improvement," aiming to reduce procurement costs, shorten lead times, and ultimately achieve customer satisfaction.

PROJECT

R-Team Lean Project Practicing "Co-prosperity" _

With a commitment to the "Co-prosperity" philosophy, Rexon introduced the lean production model in 2017. Initially implemented internally, the lean production approach resulted in significant benefits, with increased productivity per employee. Building on the success of lean production within the organization, Rexon extended the model to its supply chain in 2020. To accomplish this, Rexon formed the R-Team project, consisting of 27 key suppliers. The project was led by a vice president-level executive from the procurement department. By organizing the project and adopting a collaborative learning approach, Rexon shared its successful experiences, methodologies, and concepts of lean production with the suppliers. The R-Team project provided guidance and assistance to suppliers in analyzing, planning, and implementing lean production practices.

To support the R-Team project, Rexon engaged the expertise of professors and their team from Tunghai University, specializing in lean production. They provided coaching and training to both the participating suppliers and the members of the Rexon project team. The R-Team project team at Rexon engages in daily communication, analysis, and review with relevant departments through established mechanisms. They also hold weekly lean meetings with senior executives to report their progress and discuss further improvements. After reaching a consensus on process improvement during the discussions, relevant adjustments and further refinement are carried out in line with the principles of lean management.

- Information Gathering

- Supplier Visits and Investigations

- Initial Evaluation

- Supplier Onboarding

- Qualification Review

- Sampling and Testing

- On-site Evaluation

- Supplier Determination

- Approved Supplier Onboarding

- Quality System Development

- Selection of Approved Suppliers

- Inquiry and Price Comparison

- Order Placement and Confirmation

- Delivery Schedule and Follow-up

- Incoming Inspection and Receipt

- Quality Confirmation and Review

- Annual Supplier Evaluation Report

- Quality Evaluation

- Delivery Evaluation

- Monthly Assessment - Quality, Delivery, Cost

- Supplier Performance Monitoring

- Improvement Proposal and Review

- Excellent Performance Rewards System

- Guidance for Improvement

OF CONDUCT

Supplier Code of Conduct _

In 2023, Rexon incorporated the "Supplier Social Responsibility Compliance Clause" into the supplier evaluation survey, further driving suppliers to implement sustainable practices such as environmental sustainability, human rights protection, and resource recycling.

Rexon refers to international standards such as ISO 9001 Quality Management System, ISO 14001 Environmental Management System, ISO 45001 Occupational Health and Safety Management System, SA 8000 (Human Rights and Labor Rights), ISO 26000 (Organizational Governance, Human Rights, Labor Practices, Environment, Fair Operating Practices, Consumer Issues, Social Engagement, and Development), and the Responsible Business Alliance (RBA) Code of Conduct (Labor, Health and Safety, Environment, Ethics, Management Systems) as references. In 2023, Rexon plans to include the "Supplier Social Responsibility Compliance Clause" in the supplier evaluation survey form and consider it in the scoring process. The implementation steps are as follows:

- The Legal Department will draft the "Supplier Code of Conduct" for adherence by Rexon's business partners.

- Within the existing R-Team Lean Supply Chain organization, an ESG team will be established to provide guidance to 15 selected suppliers in the first phase of carbon inventory assessment, scheduled to take place in 2023.

- On January 9, 2023, the supply chain e-commerce platform will be upgraded. From January 4 to January 5, three education and training sessions will be conducted, involving a total of 161 suppliers. At the beginning of each session, an anti-corruption advocacy video by the Anti-Corruption Agency will be played to reiterate the company's integrity policy to the suppliers.

Product Quality and Responsibility

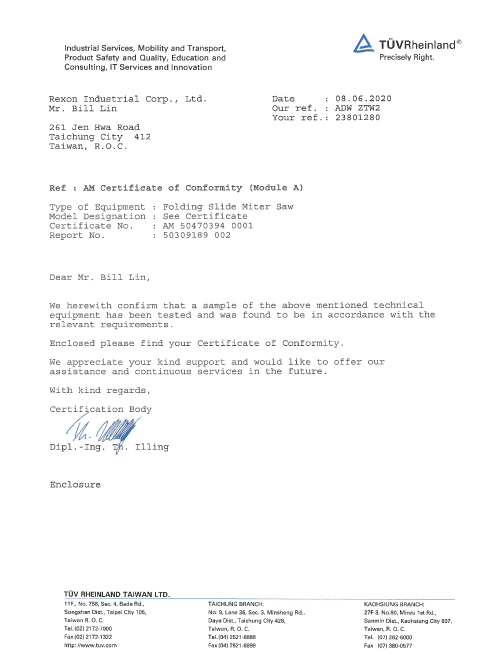

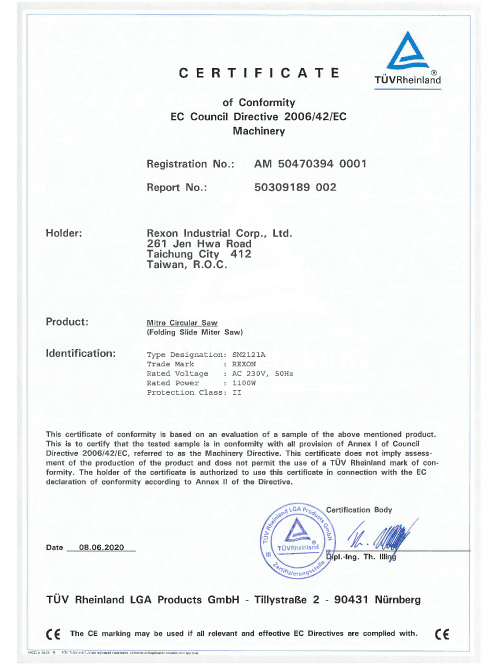

Under the implementation of the PDCA cycle management, Rexon closely follows international standards and aligns with customer industry requirements to obtain various product certifications. This ensures the quality of its products and demonstrates a sense of responsibility towards customers.

POLICY

Product Quality Policy _

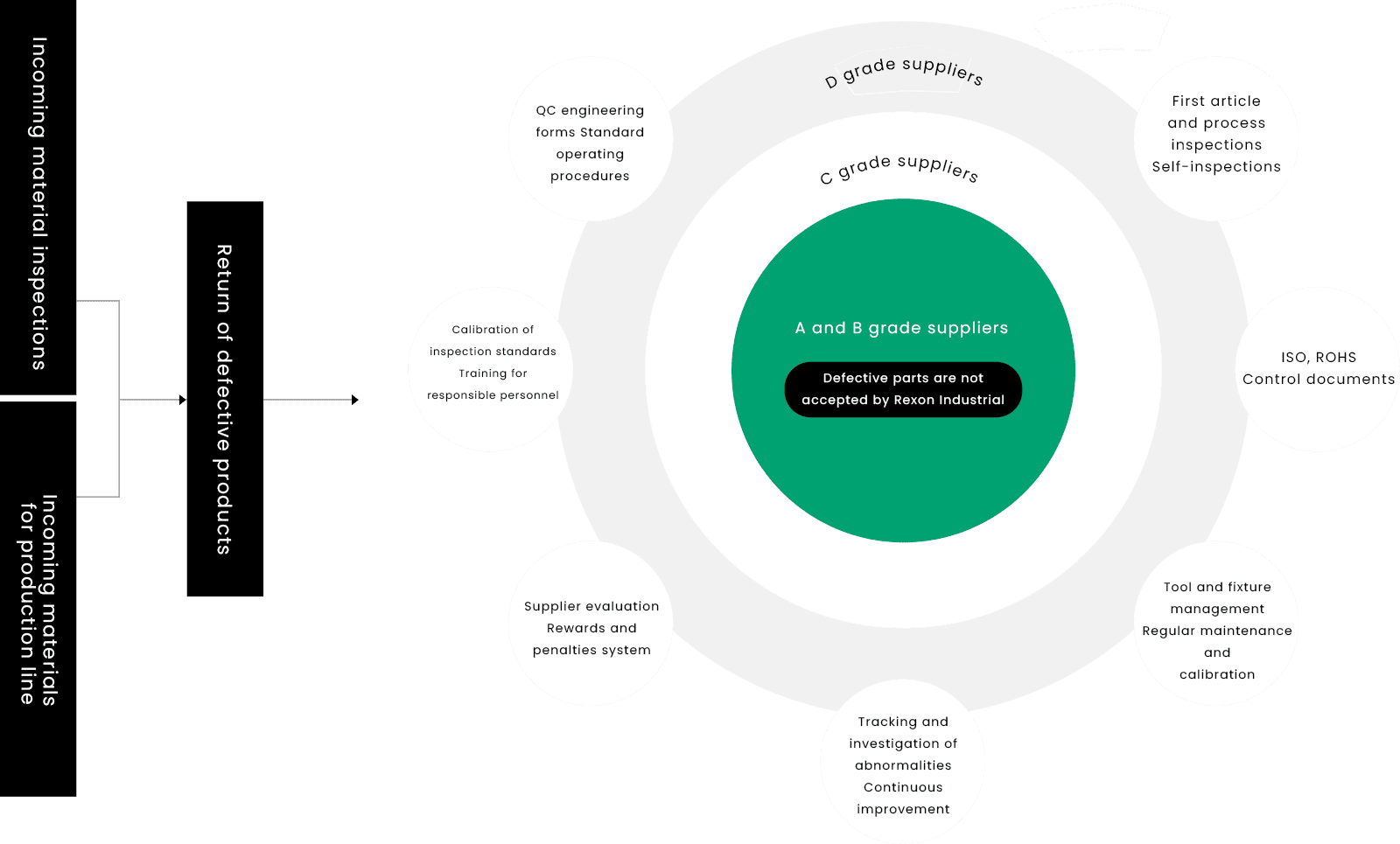

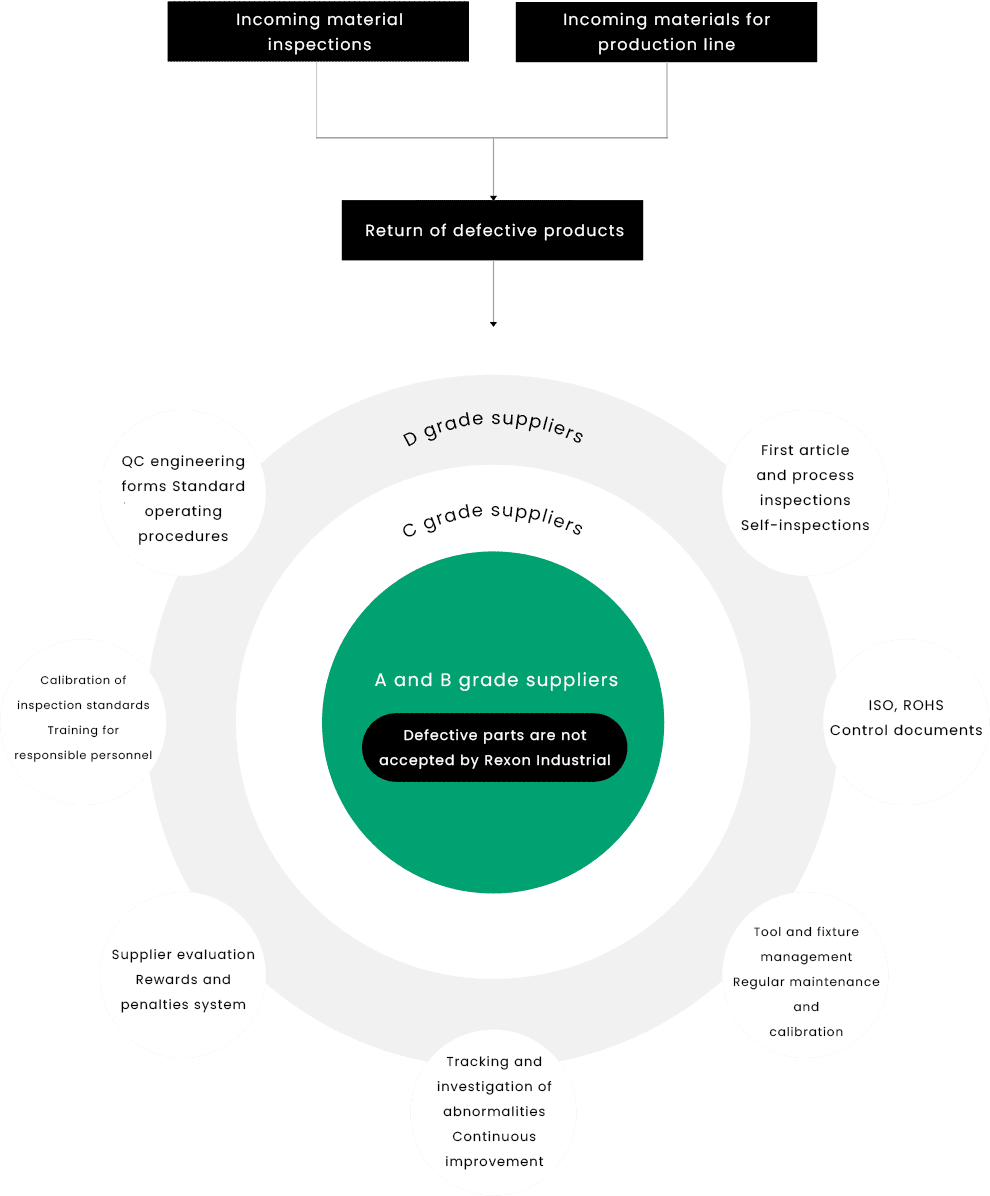

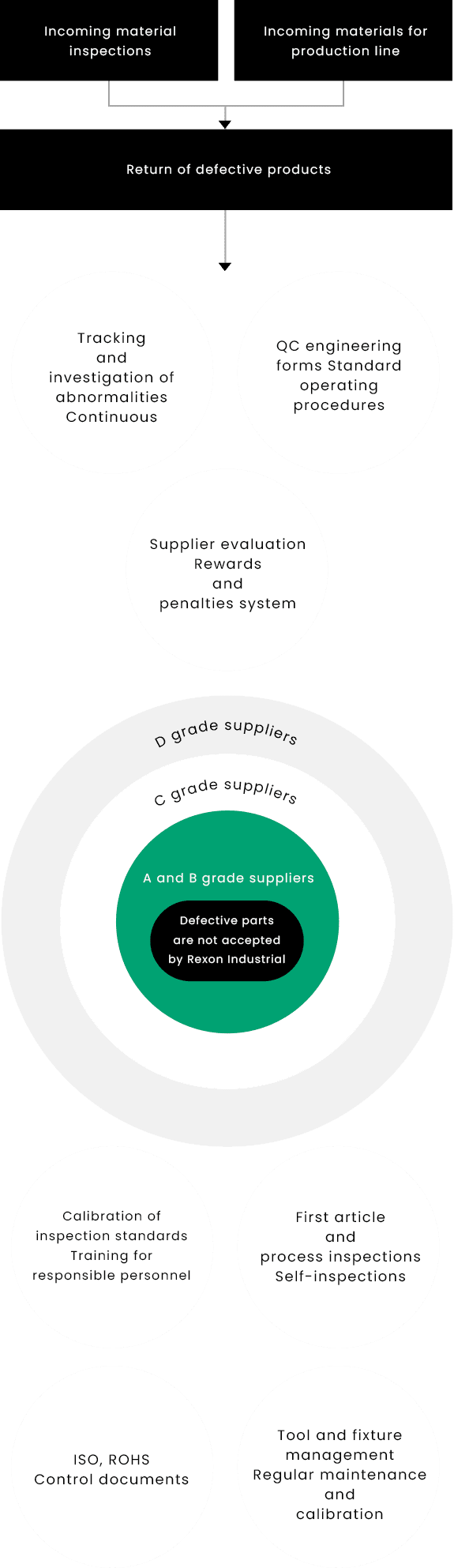

Rexon has always adhered to the three "no" policies as the company's quality culture motto: "No defective parts enter Rexon; No defective products are passed to the next process; No defective finished goods leave Rexon." To implement the quality policy effectively, the company focuses on thorough source management to ensure zero defects, quick response, and meeting market and customer demands. The quality management process and framework (as shown in the diagram) demonstrate Rexon's continuous improvement in organizational practices and methods to enhance service quality, ultimately aiming to achieve customer satisfaction.

Supplier Onboarding

- New Supplier Evaluation Review

- Supplier Survey Form

- New Product Sample Evaluation

- Quality System Investigation and Assessment

- Capacity and Manufacturing Capability Evaluation

Supplier Selection

- Production Equipment Confirmation

- Initial 5S Evaluation on-site

- Quality Management Assessment

- Sample Delivery Confirmation

Procurement Grading Management

- Supplier Evaluation Levels

- Grade A: Score of 90 and above

- Grade B: Score of 80 and above

- Grade C: Score of 70 and above

- Grade D: Score of 60 and above

Supplier Assessment

- Monthly Evaluation Mechanism

- Quality and Delivery Performance

- Registration of Qualified Supplier Parts

QUALITY CONTROL

Material Source Quality Control _

To adapt to the market trends focused on consumer orientation and shortened sales channels, Rexon has implemented thorough source management through supplier management. This ensures zero defects in quality, timely adjustments in quality policies for quick response, and listening to consumer voices to meet market and consumer needs. Rexon continuously improves its existing workflow, enhances process capabilities, and strives to meet consumer demands for products, services, and new offerings, even surpassing their expectations. Therefore, the company maintains continuous monitoring of supplier input quality and establishes a supplier guidance source control mechanism as depicted in the diagram.

LIABILITY

Product Responsibility _

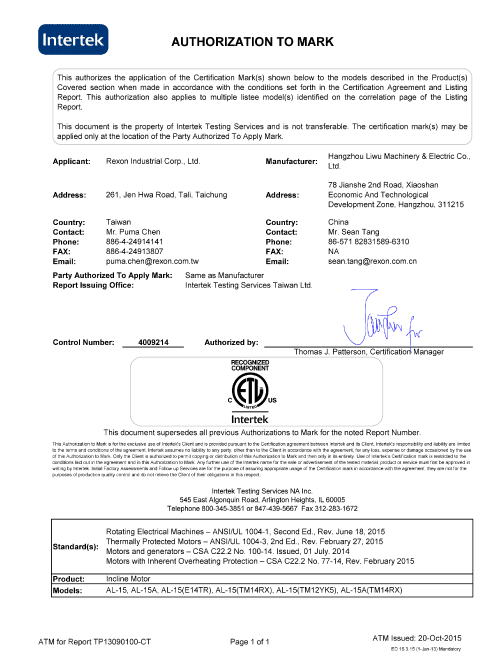

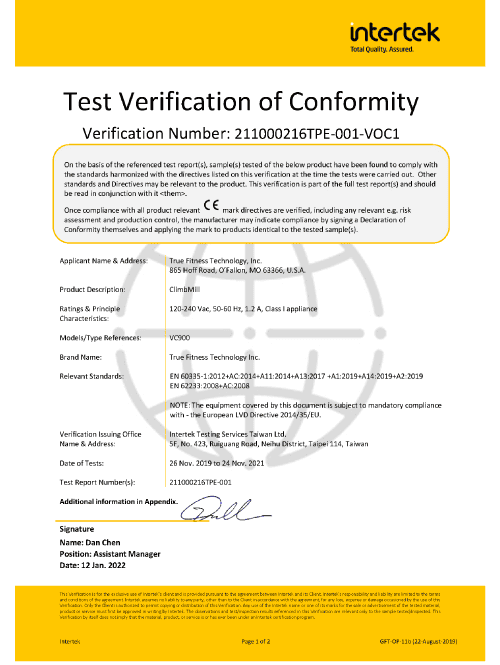

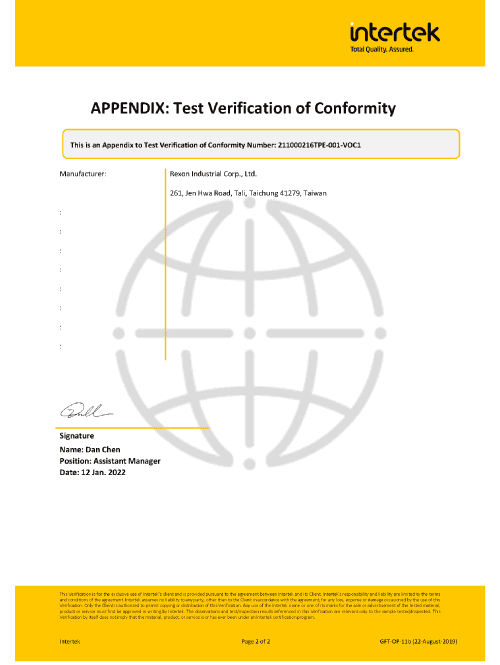

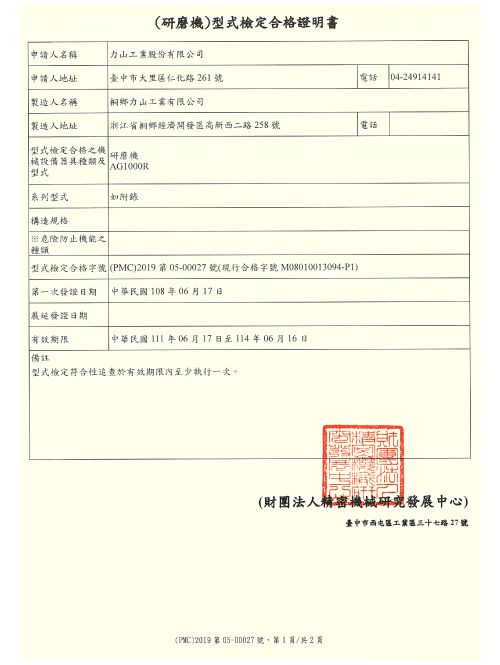

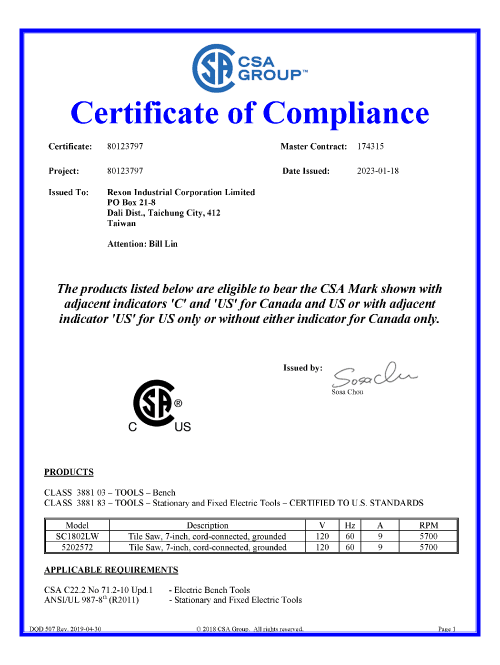

As part of its international product marketing, Rexon ensures that its sales process undergoes verification for environmental safety and uses materials that do not adversely affect consumer health. This involves obtaining validation from various environmental protection systems and complying with safety certifications specific to each sales region. (Electric Tool Product Certifications - US CUL & EU CE, Electric Tool Product Certifications - Taiwan BSMI & TS, Fitness Equipment Product Certifications - US FCC & ETL & ASTM.)

Fitness Equipment

ETL Safety Certification (US), ETLc Safety Certification (Canada), FCC Electromagnetic Interference Certification (US), ASTM Safety Certification (US), CA65 Verification (US), CE Safety Certification (EU), LVD Safety Certification (EU), EMC Electromagnetic Interference Certification (EU), EN ISO 20957 Safety Certification (EU), UKCA Safety Certification (UK), REACH (SVHC) Verification (EU), RoHS Verification (EU), INTERTEK Verification (US), TUV_SUD Verification (Germany), etc.

Power Tools

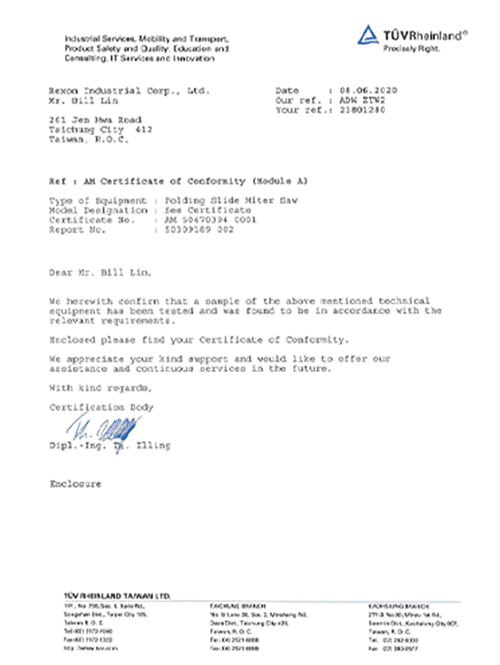

UL Safety Verification (US), CSA Safety Certification (Canada), TÜV Rheinland Verification (Germany), EMC Electromagnetic Interference Certification (EU), CE Safety Certification (EU), C-TICK Safety Verification (Australia), National Standards of the Republic of China (Taiwan), BSMI Safety Certification (Taiwan), Ministry of Labor Machinery Equipment Safety Protection Standards (Taiwan), Compulsory Certification (3C) Safety Verification (China), etc.

- Percentage = (Total evaluated products or services provided to customers / Total products or services provided to customers) × 100.

- Health and safety assessment types include: REACh/RoHS compliance, relevant testing reports, labor safety assessments, and more.

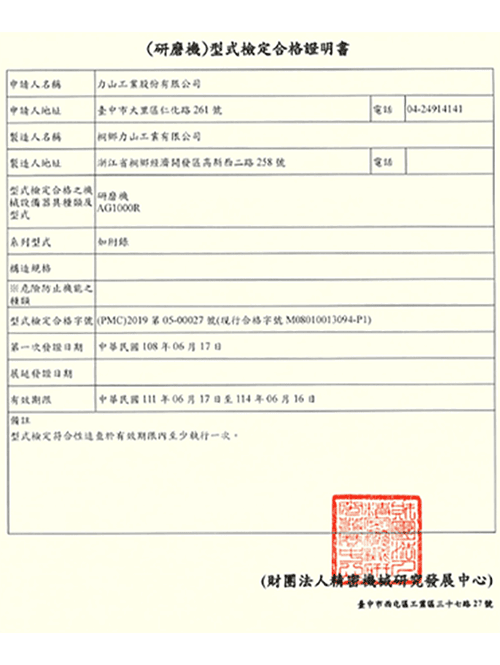

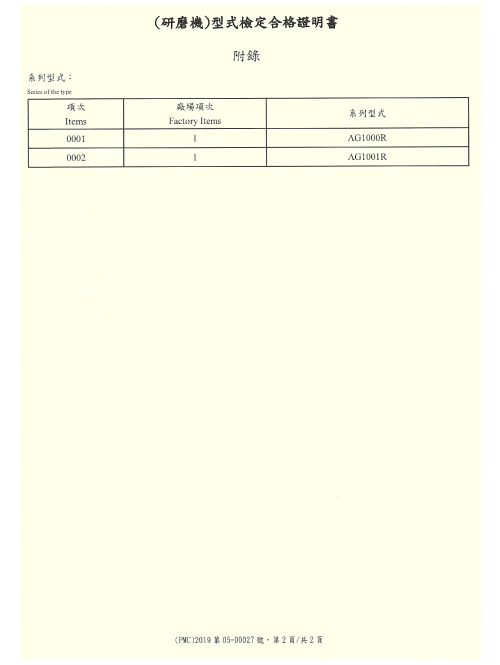

Certification for Power Tools-TS

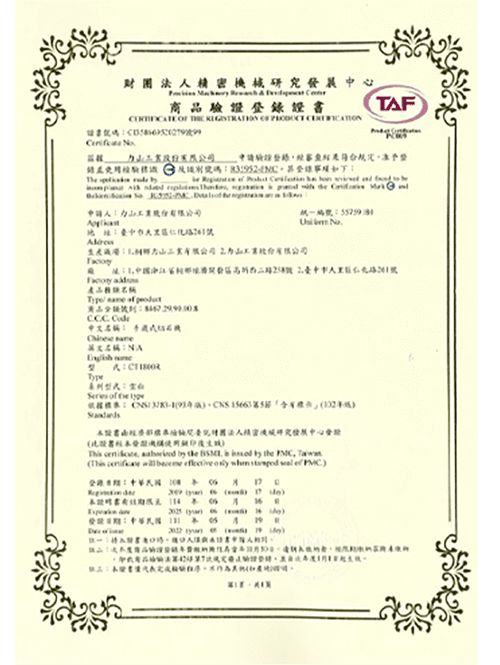

Certification for Power Tools-BSMI

Certification for Power Tools-European CE

Rexon ISO-9001 Certificate (Chinese)

Rexon ISO-9001 Certificate (English)

Certification for Fitness Equipment-American ETL

Certification for Fitness Equipment-European LVD

Certification for Fitness Equipment-European LVD

Certification for Power Tools-BSMI

Certification for Power Tools-TS

Certification for Power Tools-TS

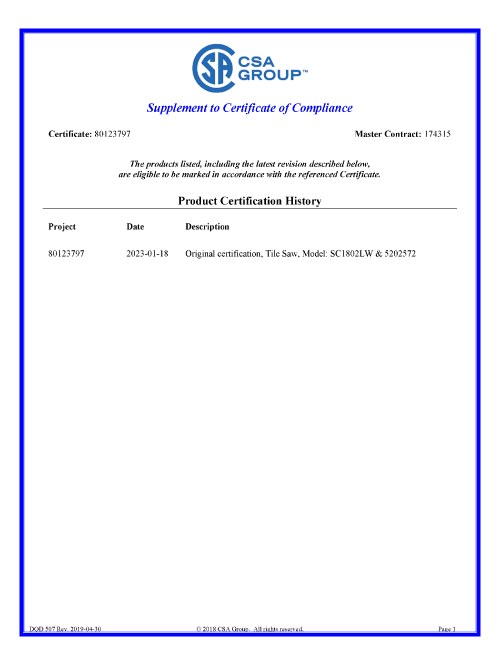

Certification for Power Tools-American CUL

Certification for Power Tools-American CUL

Certification for Power Tools-American CUL

Certification for Power Tools-European CE

Certification for Power Tools-European CE

Corporate Sustainability Development Survey

To achieve more effective communication with stakeholders who care about our company,we sincerely invite you to take the time to complete this questionnaire.

Your participation will enable us to gain a better understanding of the issues that stakeholders are concerned about and enable us to respond actively.