Korea

BIG STAR TRADING COMPANY

Taiwan

FINE CLEAR CORP.,LTD.

China

TONGXIANG REXON INDUSTRY CO., LTD.

Thailand

TIRAWAT AIR COMPRESSORS LTD.

USA

US SERVICE CENTER

Scroll

Rexon Industrial Corporation, founded in 1972, is currently one of the world's largest manufacturers of machine tools. With a global presence in over 70 countries, we specialize in the production and marketing of woodworking machinery and fitness equipment. As an ISO9001 certified company, we are committed to providing innovative and high-quality products and services to our customers. Over the past half-century, "Honesty, Stability, and Growth" has always been the group's most valued and important core values.

Rexon upholds and practices the spirit of giving back to society. We are committed to becoming a company that shareholders are happy to invest in, manufacturing products that customers are happy to purchase, and providing employees with a joyful working environment. Meanwhile, we strive to be a contributing entity to the planet. We aspire to drive positive change and foster a culture of altruism within society.

38000

factory area

1000

Number of employees

20

award recognitions

600

design patent applications

INTEGRATION

SERVICES

Rexon integrated manufacturing services _

/ 01 _

Product Design and Development

Rexon Industrial boasts a team of over 100 highly skilled and knowledgeable research and development personnel. With robust in-house development capabilities and a multitude of patented technologies, we are at the forefront of innovation. Therefore, in collaboration with our customers, we have developed a variety of products that are highly functional, safe, and energy-efficient. Our innovation and development are based on :

- Well-established development process management

- Extensive utilization of design and development software such as DFMEA/FEA

- Strong capabilities in mechatronics integration

- Fast and high-quality prototyping capabilities

/ 02 _

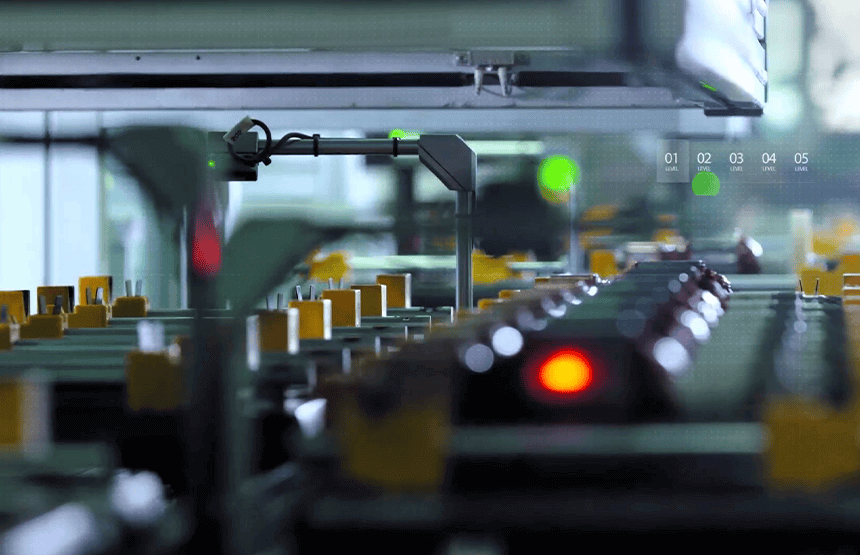

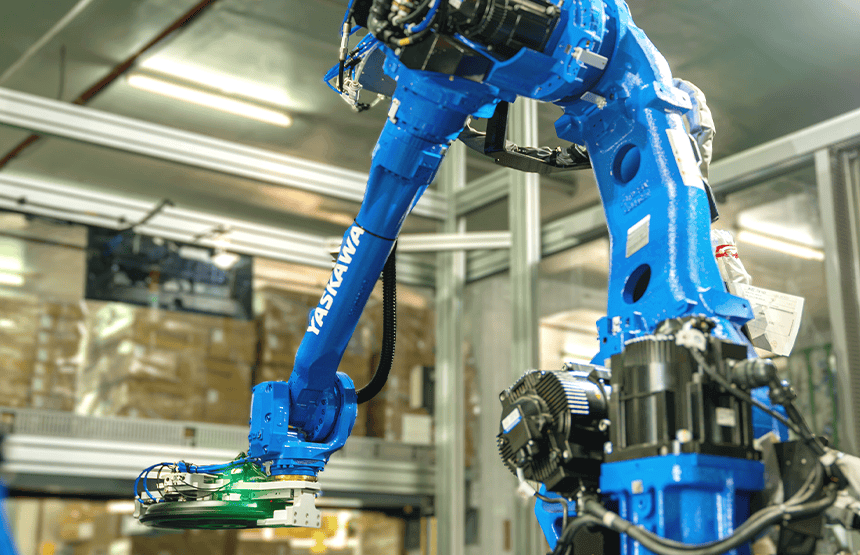

Smart Factory

Built on a foundation of exceptional manufacturing technology, Rexon Industrial not only ensures stable and ample production capacity but also actively meets the diverse needs of customers. We are dedicated to maintaining stable yields and efficient production schedule management, allowing us to consistently deliver high-quality products.

- Two major production bases: A combined total of 1,256,198 square meters of production facilities in Taiwan and Mainland China. We also have a rapid prototyping center that offers integrated services for research and development, production, and more.

- Ample production capacity: Annual production capacity exceeds 1.2 million units of fitness equipment.

- Smart manufacturing: Utilizing MES, JIT, EC platforms, and other systems to gain real-time visibility into the production process. Continuously optimizing production processes to shorten cycle times and maximize output value.

/ 03 _

Global After-Sales Service

Rexon Industrial combines online and physical service centers in North America to provide the most comprehensive and high-quality after-sales service worldwide.

- Fast online support: Our professional technical team is available online to quickly address your concerns.

- North American service center: We have a physical service center in North America, providing customers with immediate and high-quality service locally.

- Global coverage: Integrated information systems are in place to manage the service supply chain globally, ensuring our after-sales service goals are achieved.

SUSTAINABLE

DEVELOPMENT

Sustainable Development _

Just as any living being, an enterprise goes through the stages of birth, growth, maturity, and decline. Rexon is well aware of challenges of entrepreneurship and has always adhered to the spirit of "honesty, stability, and growth," which has led to outstanding achievements. We recognize that the key to sustainable business lies in innovation. Different stages of the life cycle require corresponding adaptive strategies and a spirit of innovation. This allows the ever-evolving ideas that run like a turning flywheel to continuously propel us forward, serving as the driving force behind sustainable operations. Rexon’s flywheel centers on not only lean management for design, development and production for creating maximum benefits, but also upstream and downstream benefit sharing in line with the concept of common good to allow the entire value chain revolving around innovation to spin forward.

There are two dimensions when it comes to revolving the flywheel for “sustainable management”. One is the innovation of the management model, and another is passing on the knowledge, experience and core values. The innovation of the management model covers the transformation and development of markets, customers and products. Rexon has made several breakthroughs and achievements in terms of management model innovation to achieve corporate sustainability, ranging from electric tools to fitness equipment. "Talent is the most valuable asset of an enterprise." Precise strategies and action plans can only yield results when executed by dedicated, highly loyal, and exceptional talents who wholeheartedly contribute their expertise. For Rexon, it is of utmost importance to ensure that the culmination of business wisdom and knowledge is deeply embedded in our DNA and passed on to every generation of managers. This emphasis on knowledge transfer forms a crucial part of Rexon's core values.

Production and manufacturing

Development and design

Procurement capability

End customers

BENEFIT OTHERS CREATE SOCIAL VALUE

By fostering a virtuous cycle, we propel the sustainable wheel forward. We strive to benefit both individuals and ourselves, creating the utmost value for society.